Farm Tracks and Dairy Lanes.

Table of Contents

Building Farm Tracks and Dairy Lanes.

Building a robust track for dairy farming requires a comprehensive understanding of construction principles and potential problems. This page guides you through the basic steps for constructing a sturdy and efficient track for cow traffic. It highlights the importance of constructing a strong foundation and a suitable surface layer, with emphasis on adequate compaction and drainage.

The page also includes considerations for selecting the right materials and offers examples of good and bad track surfaces. By following these guidelines, you’ll ensure the track provides a comfortable surface for cows to walk on and remains resilient against wear and tear.

Having a broad understanding of the principles.

A comprehensive understanding of the principles, processes, and potential challenges in building a track is essential for effectively managing contractors. Follow these proven race construction principles:

1. Completely remove all grass and topsoil.

2. Establish a robust base with high-quality foundational materials.

3. Ensure proper compaction throughout the structure.

4. Design a suitable walking surface for optimal comfort.

5. Implement a crown on the race for efficient water runoff.

6. Incorporate a well-designed drainage system.

7. Strategically fence out cows from the drainage areas while maintaining access for necessary cleaning.

8. Include a thorough maintenance program in the budget.

Remember, a quality track is built in layers. The foundation or base layer should be strong, supporting the surface or wearing layer above it. If the base layer is compromised, the surface layer risks breaking down.

It’s crucial to prevent water from infiltrating the base layer, as this can lead to a loss of strength and the formation of potholes.

The surface layer serves two vital functions: providing a comfortable walking surface for cows and shedding water to maintain the track’s structural integrity.

Each layer must be thoroughly compacted using vibrating rollers—relying on cow traffic alone for compaction simply does not meet the necessary standards for strength.

Ensure your construction practices embody these principles for a successful track.

Foundation (base) layer of the Farm Track.

Topsoil and grass are not suitable for use in the base layer and should be removed before beginning construction. The base should consist of layers, each up to 150 mm deep. After each 150 mm layer is laid, it should be firmly compacted before the next layer is added.

Consider the following when selecting materials: moist sub-surface soil is a suitable material. Material dug out to make effluent ponds or the material removed from the table drains may be used, provided it is not topsoil. Use gravels, pit metal, or rotten rock, but not river gravel.

Soft clay is unsuitable for use in foundations unless stabilized with other materials. Hydrated lime, evenly spread and uniformly incorporated to a depth of 125 mm, will allow soft clays to become stable once compacted. Cement can be used as a stabilizer in base layers – the usual recommendation is 1-4% of the total.

If the available material does not create a satisfactory foundation, it is possible to use a geotextile (an industrial fabric used in earthworks) to cover the shaped base layer before adding the surface layer.

Geotextiles allow water to pass through but they hold soil and rock in place and will prevent the surface layer from being pushed into the foundation layer, particularly by heavy traffic.

Surface layer of the Farm Track / Dairy Lanes.

The creation of a satisfactory track surface requires compaction into a hard, smooth, wear-resistant layer, with a minimum of particles that can cut or bruise feet. It should be 100 to 150 mm thick. Topsoil and grass provide a soft, cushioned surface for cows to walk on but are unable to withstand the rigors of frequent use.

The surface layer is usually made from a mixture of fine materials—often sand, pumice, limestone, sandstone, zeolite, wood chips, small stones, and clay. Consider the following when choosing materials: Crushed limestone (5-6 mm)—check local lime for suitability.

It is generally spread as a 50-100 mm layer and requires firm compaction. Sand alone does not make an ideal surface—it is abrasive on cows’ feet and washes away too readily. Well-rounded gravel, less than 25 mm in diameter, is preferable to large stones.

Large stones can be kicked aside, leaving the surface susceptible to water penetration and damage. Fine particles of clay will fill the gaps between larger particles, binding them together. This also gives the surface a long-wearing and smooth finish. Incorporating 0.3-1% cement into the clay capping mixture can help stabilize the surface and prolong its life.

To check if a material is appropriate for a top surface.

To check if a material is appropriate for a top surface, a small sample rock should shatter under the heel of your gumboot when ground against a concrete surface. Trialling small loads of proposed materials will show which are going to work and which are not.

Concrete tracks can be useful in areas of high rainfall as they provide a clean track and reduce mud on udders. However they do require management at the boundary between the concrete and paddocks. A section of lime fines at the intersection can help stones fall off before they get on to the concrete.

A track on a steep slope can mean water runs down the lane before running off the side – resulting in long water scours in the surface layer. Ideally, design tracks to minimise slope, even if it adds distance it will be worthwhile as maintenance issues will be reduced.

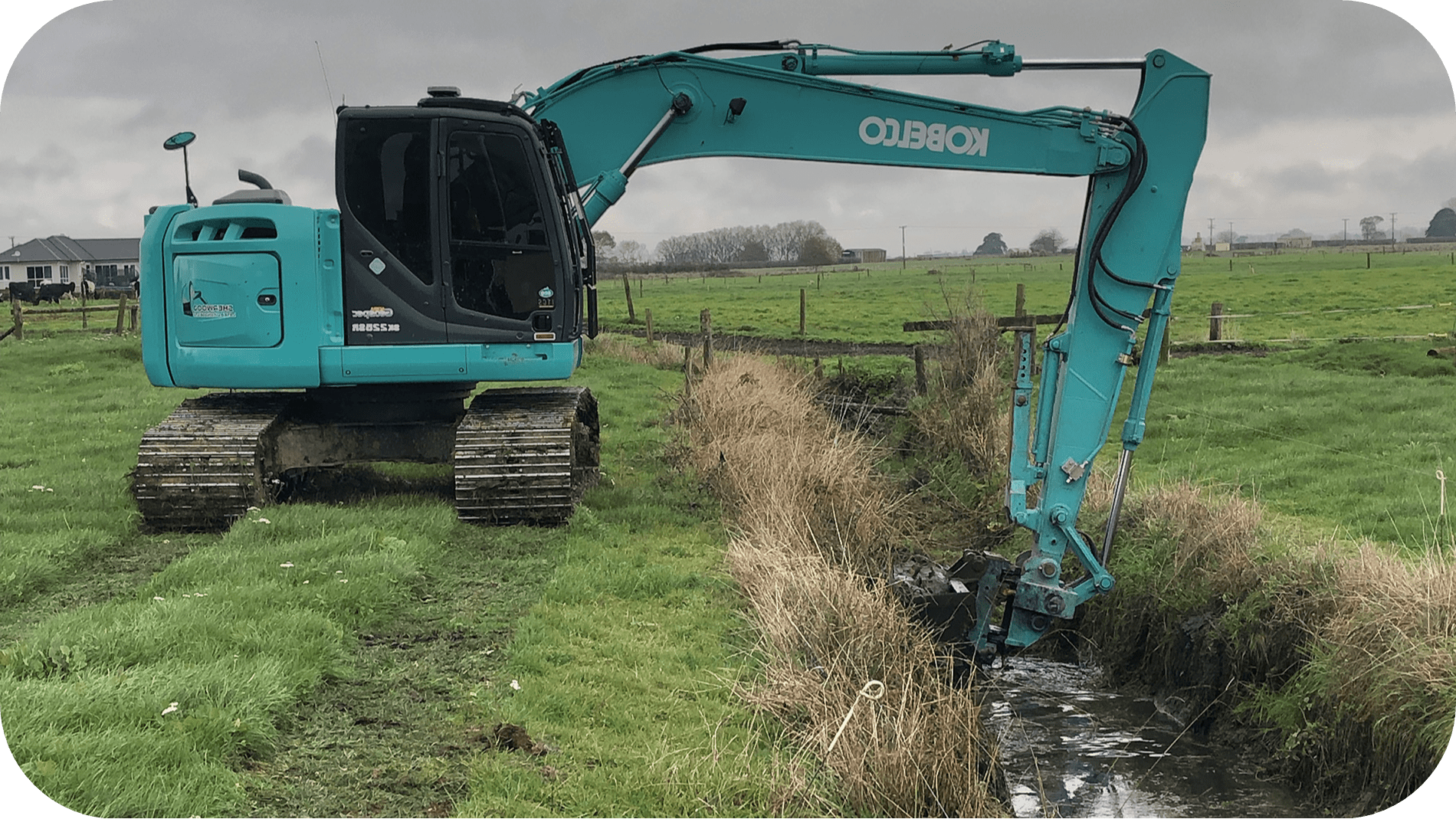

Drainage of Farm Tracks and Dairy Lanes.

Table

Creating table drains at the sides of the track helps to take water away, maintaining track condition. The recommended size for table drains is 300 mm deep and 1 metre wide.

Spur

Spur drains should be installed every 40 to 80 metres to empty the table drains on to paddocks – not to a watercourse. Spur drains should be closer together on steeper slopes.

Lateral

Small lateral drains should be cut into the tracks to allow water to flow away. Not all of the grassy edge should be removed as this is necessary to maintain the structure of the track.

Water table depth

Adequate water table depth is essential to good drainage – ensure the water table is a least 600 mm below the surface to aid the draining of water away from the track.

A water table close to the surface will hinder drainage and may cause the track to become wet, reducing its structural integrity and increasing its chance of collapse.

It may be necessary to build your track above the paddock level in areas with a high water table to ensure drainage occurs.

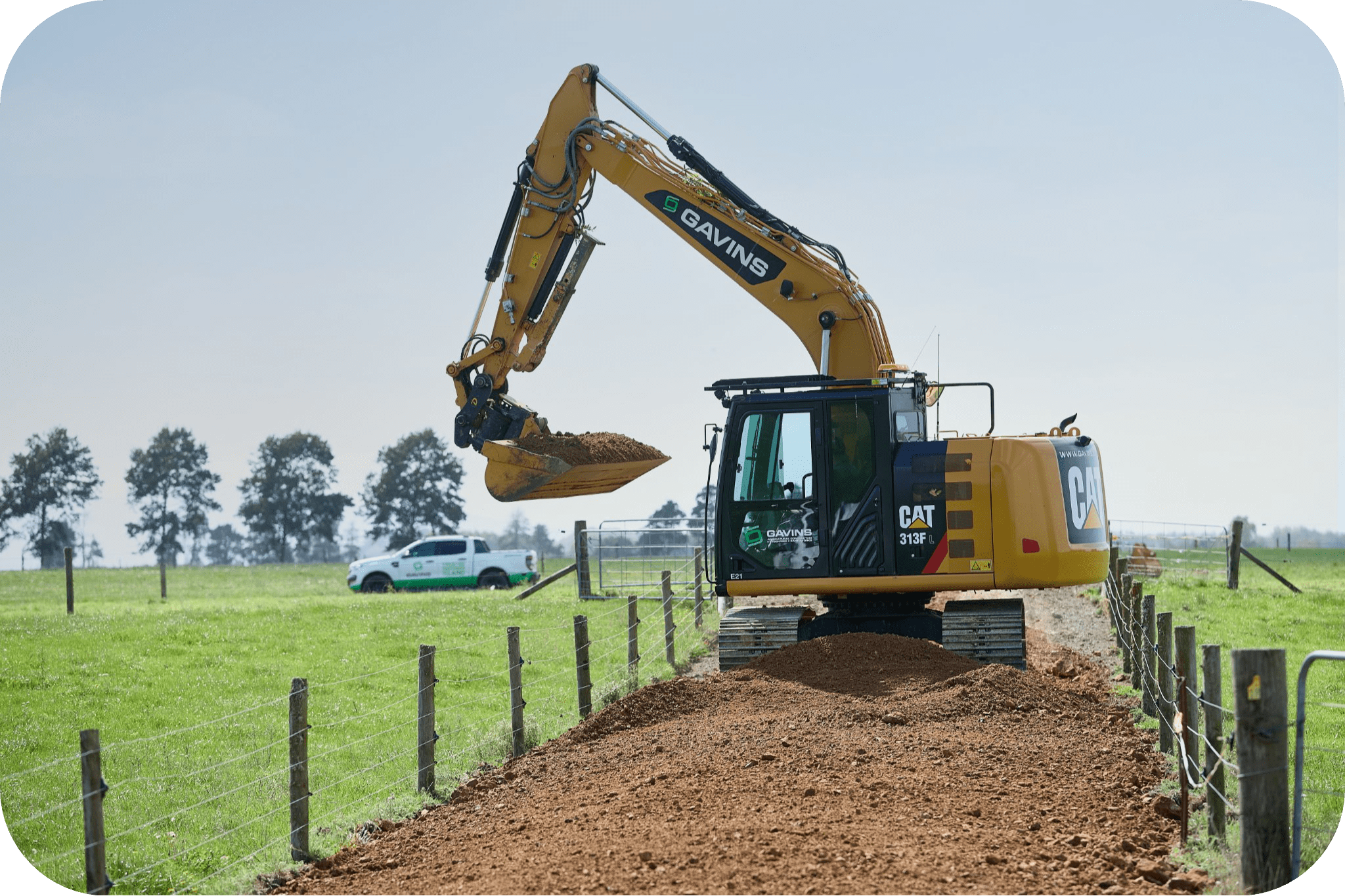

Hiring a New Earthmoving Contractor.

It’s essential to recognize that earthmoving contractors operate differently from agricultural contractors. While agricultural contractors possess some knowledge of farming practices, earthmovers often do not.

When you are having your lanes maintained or constructing new tracks, it is beneficial for you to be present for the initial hour or two. This ensures clear communication and alignment between you and the contractor.

We strongly advise taking the contractor on a farm tour to discuss any potential safety risks and ensure everything runs smoothly.

Don’t forget the basics, such as explaining which fences are live and where the toilet and smoko shed are located.

Many earthmoving businesses are small, family-owned operations.

When it comes to paying these contractors, consider how quickly you would like them to respond in the event of a significant flood or weather event?

Immediately!